YBLT900 Torque Converter

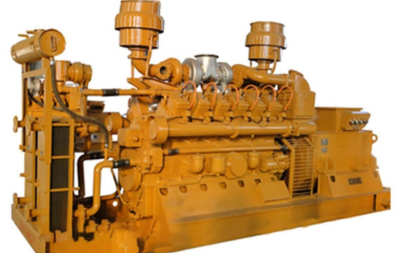

Hydraulic torque converter is a flexible transmission device installed between the power machine (such as diesel engine and electric motor) and the working machine (such as winch, rotary table and drilling pump), using mineral oil as the working medium and transmitting power of the power machine to the working machine.YBLT900 hydraulic torque converter is a centrifugal turbine torque converter with charging and adjusting valve and its working chamber diameter is 900mm.It is compatible with G12V190PZL (or CAT3512) diesel engines and is mainly used on oil rigs.

Characteristic

(1) The large zero moment coefficient and high transmission efficiency can improve the working efficiency of the drilling machine.

(2) To reduce or even eliminate the impact on the diesel engine and rig transmission parts, improve the service life.

(3) When the rig is stuck or overloaded, the diesel engine will not shut off.

(4) Even if the engine is running at full speed, the working mechanism of the rig (rotary table and drilling pump) can be operated for a long time at low speed by changing the amount of oil filled by the torque converter.

(5) With the change of external load, the torque converter automatically adjusts the output speed and torque without interruption of output power.

(6) When the load of the working mechanism is small or equal to zero, the diesel engine operates at a low speed, and the torque converter automatically realizes the minimum or zero oil filling at the same time, thus reducing the power loss.

(7) Exquisite structure arrangement, reliable work, long service life, easy installation and maintenance.

(8) Good cooling effect, working oil will not overheat.

Maximum input speed | 1500 r/min |

Maximum input power | 810kW |

Maximum input moment | 6.5k Nm |

Maximum output moment | 38.0 kNm |

Peak efficiency | 85±2% |

Cavity diameter | 900 mm |

Fuel supply pressure | 0.3~0.47 MPa |

Operating oil temperature | ≤110℃ |

Net quality | 2100kg |

Overall dimension (length × width × height) | 1330×950×1073 mm |

After-sales service

1. Pre-sales consultation, making product plans according to customer needs;

2. Sales process service, export contract template, customs clearance, barrier-free delivery;

3. After-sales service engineers to guide and train customer operators on site.

4. 24-hour global technical support.

Packing and delivery

1. The use of international general fumigation-free wooden cases, safety protection.

2. International standard container size; Save save.

3. A variety of transportation methods and routing options to ensure the safe arrival of goods.