12V175 diesel engine has the characteristics of high pressure, low energy consumption, high reliability and long life. By using new technologies such as electronic control, high pressure common rail, Miller cycle, tail gas after-treatment and high efficiency supercharger, the engine power, economy, reliability and emission index have reached the international advanced level.

Contact Now

140 series engine is applicable to oil truck-mounted drilling rigs, mobile power stations, emergency power supply, engineering machines and trucks. The engine performance parameters reached advanced international standards.Engine code 140Pre-mixing before turbochargeAir and gas mixed before compressor, low requirement for gas inlet pressure.Air and gas mixed in long pipe, well mixedDigital ignition controlle

Contact Now

Working mediumNatural gas, coal bed gas, shale gas, oil field associated gas, flash vapor, air, nitrogen, carbon dioxide, hydrogen, nitrogen hydrogen and so on.Spare parts supplyAccording to the loss of supporting parts, such as connecting rod, cross head, compression cylinder, distance plate, power piston, piston rod, power cylinder head, compression piston, compression piston rod, bearing bush, connecting rod bearing bush, copper bearing bush, cross head pin, air valve assembly, etc., the company has established a compressor spare parts library, which covers all kinds of parts and has suffic

Contact Now

During the operation of the engine, metal scraps, dust, carbon deposits oxidized at high temperatures, colloidal sediments, and water are constantly mixed with lubricating oil. The role of the oil filter is to filter out these mechanical impurities and glia, keep the lubricating oil clean, and extend its service life.

Contact Now

We have the most professional service, the best quality inspection system, we assure you that the accessories you receive are qualified, the best quality, the longest life, and of course the best cost performance.

Contact Now

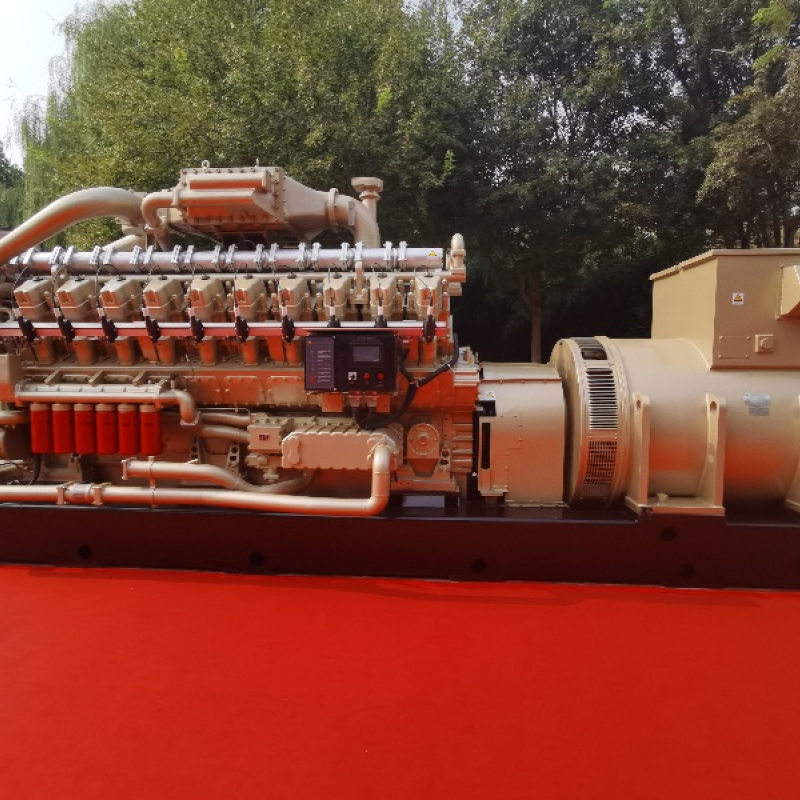

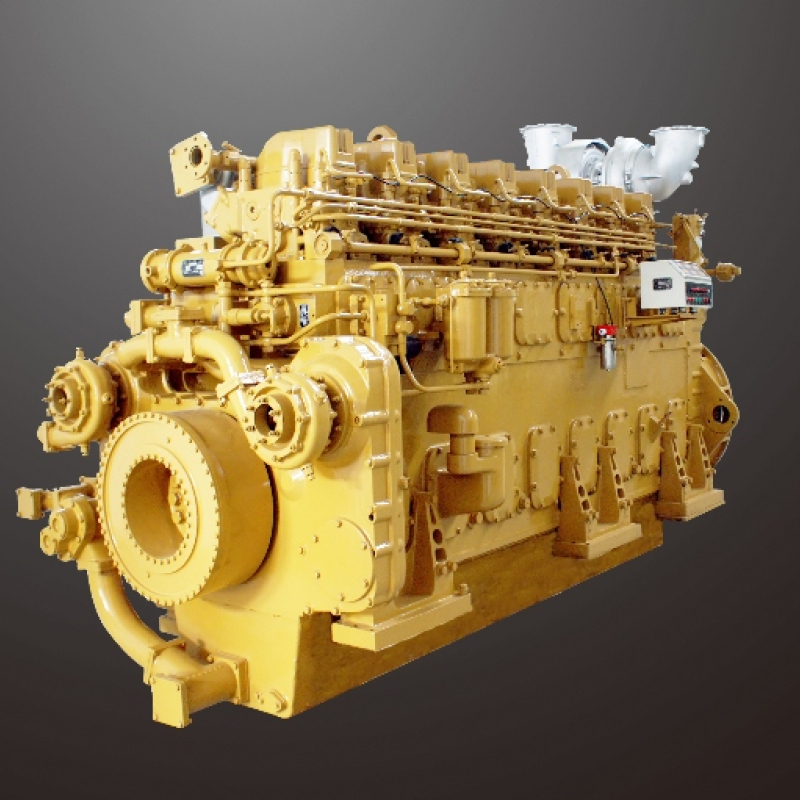

Series 6000 land-used diesel engine is developed by using Jichai with Austria AVL enterprise and home generic faculties and universities, lookup institutes, and by usingcapacity of the modern day improvement of inner combustion engine, thru the computer-aided design, simulation, finite aspect evaluation and lookup on the combustion process, the crankshaft torsional vibration of engine and turbocharger matching, into the exhaust machine on the groundwork of

Contact Now

The 140 series engine is another small-bore unit jointly developed by Jichai and AVL, which is a high-performance high-speed engine with full intellectual property rights of the company.

Contact Now

Series 6000 land-used diesel engine is developed by Jichai with Austria AVL company and domestic well-known colleges and universities, research institutes, and by means of the latest development of internal combustion engine, through the computer-aided design, simulation, finite element analysis and research on the combustion process, the crankshaft torsional vibration of engine and turbocharger matching, into the exhaust system on the basis of the simulation, optimization of design and development.

Contact Now

This series of products adopts the most advanced automatic air-fuel ratio control technology; Its technical indicators in the engine performance, fuel economy, reliability and safety and other aspects of similar products have been greatly improved, the comprehensive performance indicators have reached the international advanced level, can be used with gas generating units and compressor units, but also to meet the needs of the city and well site power supply and compressor market.Product feature:Impartial mental property rightsInternational mainstream Control Technology (EGS Engine I

Contact Now

CNPC Chai Gas (coal bed methane) power generation products were first used in Jincheng area in 2003. Since 2005, the company has increased r&d investment in coal mine gas power generation products, paid attention to communication and cooperation with relevant research institutes of coal mines, and established close ties with China Coal Bed Methane Society, Henan University of Science and Technology, Fushun Coal Branch General Institute and other coal design institutes.

Contact Now

CNPC Ji Chai Gas (coal bed methane) power generation products were first used in Jincheng area in 2003. Since 2005, the company has increased r&d investment in coal mine gas power generation products, paid attention to communication and cooperation with relevant research institutes of coal mines, and established close ties with China Coal Bed Methane Society, Henan University of Science and Technology, Fushun Coal Branch General Institute and other coal design institutes.

Contact Now

CNPC Chai Gas (coal mattress methane) electricity technology merchandise had beenfirst used in Jincheng region in 2003.

Contact Now

Jichai is a domestic leader in high-power gas engines, and has been committed to the development and manufacturing of gas-fueled engine products. At present, the company has developed multi-power segment and various specifications of gas engines, 1512 series gas engines, which adopt WOODWARD's gas mixing technology, advanced electronic control and lean combustion technology.

Contact Now

Product descriptionLandfill gas engine generators are well-established products in our product line. After years of painstaking research, the product incorporates the rich profit-making experience of the 12V190 gas engine, and the automation function of the unit is significantly enhanced. Reliable air-fuel ratio automatic control technology enables the unit to have higher gas applicability, stronger comprehensive performance and economy, and successfully reduces the emission index to the minimum.

Contact Now

Jichai began developing high-power turbocharged natural gas engines in 1982. From 1984 to 1988, three prototype tests were carried out in the laboratory, 10,000 hours of industrial tests were carried out in Shengli Oilfield, and on October 12, 1988, it was recognized by the state as a 600kW/1000r/min external hybrid supercharged high-power gas engine.

Contact Now

L20V1902LT-2type closed-loop electrically controlled external mixing natural gas machine features:1、Turbocharger pre-mixing technology, where gas and air are sucked in at the same time in the compressor, to be suitable for low pressure gas,2,The rarefied combustion technology uses WOODWARD's E6 control system to accurately control the air-fuel ratio.Reach the high - altitude combustion ratio, achieve rarefied combustion3,The single point injection and air - fuel ratio closed - loop control technology can realize the closed - loop control of air - fuel ratio (in).The engine can adjust

Contact Now

Turbocharger pre-mixing technology, where gas and air are sucked in at the same time in the compressor, to be suitable for low pressure gas.Rarefied combustion technology, WOODWARD's E6 control system is used to control the air-fuel ratio accurately to reach the high - altitude combustion ratio, rarefied combustion.The single point injection and air - fuel ratio closed - loop control technology can realize the closed - loop control of air - fuel ratio (in).The engine can adjust the amount of air and natural gas according to the requirements of different working conditions and different spe

Contact Now

L20V1902LT-2 type closed-loop electrically controlled external mixing natural gas machine features:1、Turbocharger pre-mixing technology, where gas and air are sucked in at the same time in the compressor, to be suitable for low pressure gas,2,Rarefied combustion technology,WOODWARD's E6 control system is used to control the air-fuel ratio accurately to reach the high - altitude combustion ratio, rarefied combustion3,The single point injection and air - fuel ratio closed - loop control technology can realize the closed - loop control of air - fuel ratio (in).The engine can adjust the amount

Contact Now

100% independent intellectual property rightsInternational mainstream Control Technology (EGS Engine Intelligent Management System))International advanced air-fuel ratio control technology (TECJET air-fuel ratio automatic regulation)Large flow and high pressure intake system can adapt to a wide range of concentration changesLow pressure intake and rarefied combustion control technology (suitable for low pressure gas, better emission)Advanced genset management module (IG-NT automatic synchronization and automatic load distribution)Online maintenance technology (continuous trouble-free operation

Contact Now

Product feature:100% intellectual property of companyInternational Control Technology (EGS Engine Management System))International mainstream air-fuel ratio control technology (TECJET air-fuel ratio automatic regulation management system)Large flow and high pressure intake automatic management system of adapting to a wide range of concentration changesLow pressure intake and rarefied gas combustion control technology (suitable for low pressure gas, lower emission)Engine seriesEngine modelEngine modelH16V190ZLT-1 gas engineCylinders & Arrangement16 cylinders V typeCylin

Contact Now

The gearbox can be used to reduce the speed and load of transport ships and engineering ships. It can meet the requirements of gas and electricity double starting, remote operation, engine parallel and so on.The products cover a wide range of power, can meet the needs of customers in different power segments, products have passed the CCS certification.

Contact Now

The product design is based on a 12V26/32 diesel engine, whose fuel involves diesel, heavy oil and natural gas. It is a high pressure engine with full intellectual property rights jointly developed by Geichai and AVL of Austria. It is a series of engines with 100% intellectual property rights, medium speed supercharged, great success, low fuel consumption, high reliability and long life, jointly developed by Geichai and AVL of Austria.

Contact Now

Fast response service, complete quality system, huge storage system, fast logistics system; These are our professional embodiment, do accessories we are professional.

Contact Now

The above tools are necessary special tools in the operation and maintenance process of the equipment, which are specially designed by our company to facilitate the maintenance, inspection and regular maintenance of the equipment, and play a convenient and easy-to-use role in the disassembly and installation of important components.

Contact Now