The efficiency of its air exchange is higher than that of the natural intake of the general engine. When the air enters the turbocharger, its temperature will rise significantly, and the density will become smaller accordingly. The intercooler plays the role of cooling the air, and the high-temperature air is cooled by the intercooler and then enters the engine. If the lack of an intercooler and let the pressurized high temperature air directly into the engine, it will cause the engine to knock or even damage the flame.

Contact Now

We are one of the most advanced professional spare parts suppliers in China.To provide you with qualified, high-quality and inexpensive accessories is our goal, equipment safe and efficient operation is the purpose; Accessories supply is the basis; The safe and efficient operation of the equipment is our common pursuit.

Contact Now

We have the most professional service, the best quality inspection system, we assure you that the accessories you receive are qualified, the best quality, the longest life, and of course the best cost performance.

Contact Now

We have the most complete parts production and manufacturing system, storage system and transportation system to ensure that parts arrive in a fast way;We are one of the leading professional spare parts manufacturers and suppliers in China.

Contact Now

1, we have the most complete parts production and manufacturing system, storage system and transportation system, to ensure that parts arrive in a fast way;2, we have the most professional service and the best quality inspection system, to ensure that the accessories you receive are qualified, the best quality, the longest life.3, accessories are packed in cartons or wooden cases, fumigation-free, waterproof and moisture-proof, the safest protection.

Contact Now

Accessories Policy:Quality and customer first, excellent service and quality based on the guarantee of parts life.Warranty: The warranty period of the compressor unit is 8,000 hours from the date of first operation after the completion of the installation acceptance test; Or within 1 year from the date of delivery (whichever comes first).

Contact Now

The above tools are necessary special tools in the operation and maintenance process of the equipment, which are specially designed by our company to facilitate the maintenance, inspection and regular maintenance of the equipment, and play a convenient and easy-to-use role in the disassembly and installation of important components.

Contact Now

High pressure steel wire braided hose operating temperature: oil -40℃ ~ 100℃, air -30℃ ~ 50℃, water emulsion +80℃ below.High pressure steel wire braided hose specification range: DN5mm ~ DN102mm.

Contact Now

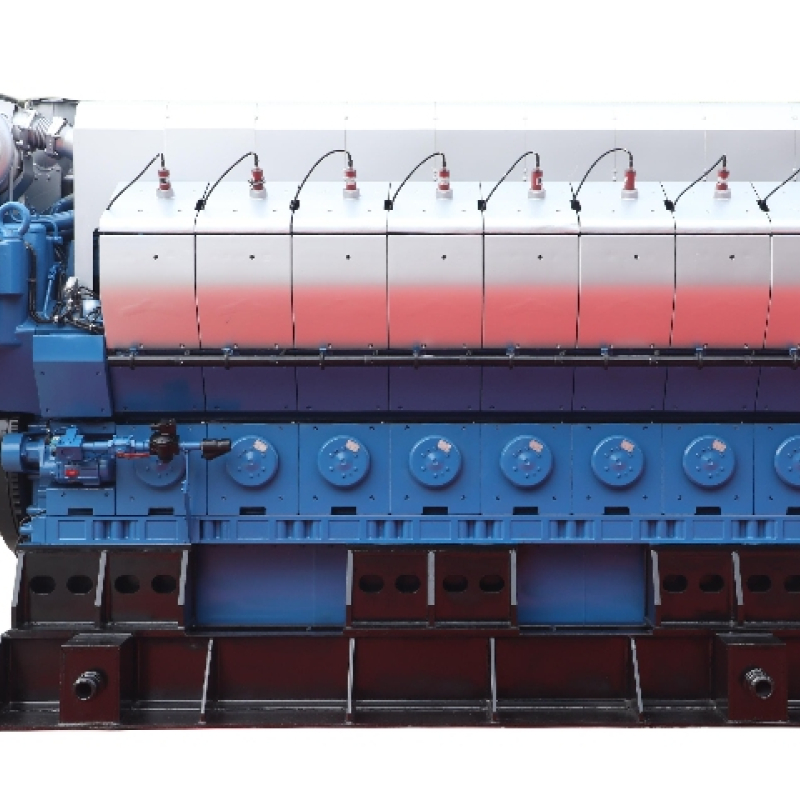

140 series engine is applicable to oil truck-mounted drilling rigs, mobile power stations, emergency power supply, engineering machines and trucks. The engine performance parameters reached advanced international standards.Engine code 140Pre-mixing before turbochargeAir and gas mixed before compressor, low requirement for gas inlet pressure.Air and gas mixed in long pipe, well mixedDigital ignition controlle

Contact Now

This series product is the new hydraulic coupling reducer developed by our company for the solid control circulation system of drilling mud pump.The combination of fixed pipe oil discharge and inlet valve control is adopted to adjust the speed, which has the advantages of starting with load, overload protection, isolating torsion-vibration, reducing impact, stepless speed regulation and fast and steady clutch.

Contact Now

The electric motor coupling power unit is driven by electric motors and makes full use of power grid resources, which realizes the electric driving transformation of traditional mechanical drilling machine, reduces drilling cost, improves economic benefits, effectively reduces drilling noise, and has no exhaust emission, thus greatly improving the working environment.The unit is powered by a high-power electric motor, and users can make full use of cheap grid power resources to reduce the drilling cost by 30% ~ 45%.

Contact Now

One of the direct consequences of the blockage of the supercharger channel is to increase the resistance of the airflow in the system. When the engine is running, the gas flow route of the pressurization system is: compressor inlet filter and muffler → compressor impeller → compressor diffuser → air cooler → scavenging box → diesel engine intake port (valve) → exhaust port (valve) → exhaust pipe → exhaust turbine nozzle ring → exhaust turbine impeller → chimney. The circulation area of each component is fixed.

Contact Now

In order to meet the market demand of long-distance pipeline compressor drive power, offshore drilling platform power, large gas power station, distributed energy and other market demand, 3MW natural gas engine came into being, the product adopts 26/32 series gas engine, with independent intellectual property rights.

Contact Now

Jichai began developing high-power turbocharged natural gas engines in 1982. From 1984 to 1988, three prototype tests were carried out in the laboratory, 10,000 hours of industrial tests were carried out in Shengli Oilfield, and on October 12, 1988, it was recognized by the state as a 600kW/1000r/min external hybrid supercharged high-power gas engine.

Contact Now

The piston works under high temperature, high pressure, high speed and poor lubrication.

Contact Now

According to the characteristics of oilfield working conditions, the genset has been designed in terms of starting performance, sudden reduction capacity and continuous working capacity.

Contact Now

During the operation of the engine, metal scraps, dust, carbon deposits oxidized at high temperatures, colloidal sediments, and water are constantly mixed with lubricating oil. The role of the oil filter is to filter out these mechanical impurities and glia, keep the lubricating oil clean, and extend its service life.

Contact Now

Fast response service, complete quality system, huge storage system, fast logistics system; These are our professional embodiment, do accessories we are professional.

Contact Now

Smooth operation, low noise. The number of rotor teeth inside and outside the cycloidal rotor pump is only one tooth, when they do relative movement, the sliding speed of the tooth surface is small, and the mesh point is constantly moving along the tooth profile of the internal and external rotor, so the two rotor tooth surfaces wear each other less.

Contact Now

The O-ring friction resistance is small, the dynamic and static friction force is equal, is the "0" shape rubber ring friction 1/2-1/4, can eliminate the "crawling" phenomenon of low speed, low pressure movement.The O-ring has high wear resistance and automatic elastic compensation function after the sealing surface is worn.O-rings have good self-lubricating properties.

Contact Now

We are one of the professional component suppliers and manufacturers in China;Our products are available globally; We have meticulous and professional services; We have a complete warehousing and transportation system.

Contact Now

Technical Characteristics

1,Designed and manufactured as per API613 and ISO13631.;

2,Horizontally and symmetrically balanced sructure,with an accurate weight diference in reciprocating parts in each row,can effectively balance the inertia force and inetia moment,so that the compressor unit can operate with a small vibration and a low noise;

3.Highly stiff bare compressor mectanism optimized via mechanical treatment can eliminate wall surface vertical to force drection,so that the bearing capacity can be increased;

4.Bearing surtace of transmlsslon part is suoject to a low tpecific pressure val

Contact Now

Filter element removal tool partsSpark plug sleevePiston fixtureParts of the turning mechanismThe above general special tools are provided free of charge at the time of delivery; These tools are used in the daily maintenance of the equipment to facilitate customers to grasp the status of the equipment in time.

Contact Now

The role of the cylinder head is to seal the gas, form a combustion space with the piston, and withstand the role of high temperature and high pressure gas. The working condition of the cylinder head is: (1)the cylinder head is subjected to the action of high temperature and high pressure gas, and bears a large bolt pre-tightening force, resulting in large mechanical stress. (2)The structure of the cylinder head is complex, and the temperature field is seriously uneven, resulting in large thermal stress, which will cause cracks and overall deformation of the cylinder head

Contact Now