Accessories Policy:Quality and customer first, excellent service and quality based on the guarantee of parts life.Warranty: The warranty period of the compressor unit is 8,000 hours from the date of first operation after the completion of the installation acceptance test; Or within 1 year from the date of delivery (whichever comes first).

Contact Now

L20V1902LT-2 type closed-loop electrically controlled external mixing natural gas machine features:1、Turbocharger pre-mixing technology, where gas and air are sucked in at the same time in the compressor, to be suitable for low pressure gas,2,Rarefied combustion technology,WOODWARD's E6 control system is used to control the air-fuel ratio accurately to reach the high - altitude combustion ratio, rarefied combustion3,The single point injection and air - fuel ratio closed - loop control technology can realize the closed - loop control of air - fuel ratio (in).The engine can adjust the amount

Contact Now

Engine and compressor share one frame and one crankshaft,subject to symmetrically balanced arrangement,so that inertia force and inertia moment can be well balanced and vibration is small;Internal mixing gas injection and loop scavenging can effectively cool and clean cylinders,thereby ensuring that fuel can be controlled and saved;lsolated room of compressed air between compressor frame and engine piston can effectively prevent combustion exhaust from releasing to oil sump,prevent pollutions by lubricating oil and extend the service life;Power cylinder has a simple structure,wi

Contact Now

140 series engine is applicable to oil truck-mounted drilling rigs, mobile power stations, emergency power supply, engineering machines and trucks. The engine performance parameters reached advanced international standards.Engine code 140Pre-mixing before turbochargeAir and gas mixed before compressor, low requirement for gas inlet pressure.Air and gas mixed in long pipe, well mixedDigital ignition controlle

Contact Now

Technical Characteristics

1,Designed and manufactured as per API613 and ISO13631.;

2,Horizontally and symmetrically balanced sructure,with an accurate weight diference in reciprocating parts in each row,can effectively balance the inertia force and inetia moment,so that the compressor unit can operate with a small vibration and a low noise;

3.Highly stiff bare compressor mectanism optimized via mechanical treatment can eliminate wall surface vertical to force drection,so that the bearing capacity can be increased;

4.Bearing surtace of transmlsslon part is suoject to a low tpecific pressure val

Contact Now

In order to meet the market demand of long-distance pipeline compressor drive power, offshore drilling platform power, large gas power station, distributed energy and other market demand, 3MW natural gas engine came into being, the product adopts 26/32 series gas engine, with independent intellectual property rights.

Contact Now

Working mediumNatural gas, coal bed gas, shale gas, oil field associated gas, flash vapor, air, nitrogen, carbon dioxide, hydrogen, nitrogen hydrogen and so on.Spare parts supplyAccording to the loss of supporting parts, such as connecting rod, cross head, compression cylinder, distance plate, power piston, piston rod, power cylinder head, compression piston, compression piston rod, bearing bush, connecting rod bearing bush, copper bearing bush, cross head pin, air valve assembly, etc., the company has established a compressor spare parts library, which covers all kinds of parts and has suffic

Contact Now

Jichai is a domestic leader in high-power gas engines, and has been committed to the development and manufacturing of gas-fueled engine products. At present, the company has developed multi-power segment and various specifications of gas engines, 1512 series gas engines, which adopt WOODWARD's gas mixing technology, advanced electronic control and lean combustion technology.

Contact Now

Turbocharger pre-mixing technology, where gas and air are sucked in at the same time in the compressor, to be suitable for low pressure gas.Rarefied combustion technology, WOODWARD's E6 control system is used to control the air-fuel ratio accurately to reach the high - altitude combustion ratio, rarefied combustion.The single point injection and air - fuel ratio closed - loop control technology can realize the closed - loop control of air - fuel ratio (in).The engine can adjust the amount of air and natural gas according to the requirements of different working conditions and different spe

Contact Now

One of the direct consequences of the blockage of the supercharger channel is to increase the resistance of the airflow in the system. When the engine is running, the gas flow route of the pressurization system is: compressor inlet filter and muffler → compressor impeller → compressor diffuser → air cooler → scavenging box → diesel engine intake port (valve) → exhaust port (valve) → exhaust pipe → exhaust turbine nozzle ring → exhaust turbine impeller → chimney. The circulation area of each component is fixed.

Contact Now

L20V1902LT-2type closed-loop electrically controlled external mixing natural gas machine features:1、Turbocharger pre-mixing technology, where gas and air are sucked in at the same time in the compressor, to be suitable for low pressure gas,2,The rarefied combustion technology uses WOODWARD's E6 control system to accurately control the air-fuel ratio.Reach the high - altitude combustion ratio, achieve rarefied combustion3,The single point injection and air - fuel ratio closed - loop control technology can realize the closed - loop control of air - fuel ratio (in).The engine can adjust

Contact Now

It can be used in gas injection, gas drilling, pipeline pressure testing and other fields.Gas inlet pressure1.0~2.4MPaGGas OUTlet pressure17~50MPaGas displacement 25~100Nm3/minWork Mode24 continous working modeAfter-sales service1. You can communicate directly with us through email, social media, online websites, etc.;2. You can visit the factory to determine the most suitable products for you;3.

Contact Now

This series of products adopts the most advanced automatic air-fuel ratio control technology; Its technical indicators in the engine performance, fuel economy, reliability and safety and other aspects of similar products have been greatly improved, the comprehensive performance indicators have reached the international advanced level, can be used with gas generating units and compressor units, but also to meet the needs of the city and well site power supply and compressor market.Product feature:Impartial mental property rightsInternational mainstream Control Technology (EGS Engine I

Contact Now

The series of products in the engine performance, fuel economy, reliability and safety have been greatly improved, its main performance indicators have reached the international advanced level, the series of products can be used with compressor units and gas generator sets, to meet the needs of urban blocks and drilling sites power supply and compressor market.

Contact Now

Jichai began developing high-power turbocharged natural gas engines in 1982. From 1984 to 1988, three prototype tests were carried out in the laboratory, 10,000 hours of industrial tests were carried out in Shengli Oilfield, and on October 12, 1988, it was recognized by the state as a 600kW/1000r/min external hybrid supercharged high-power gas engine.

Contact Now

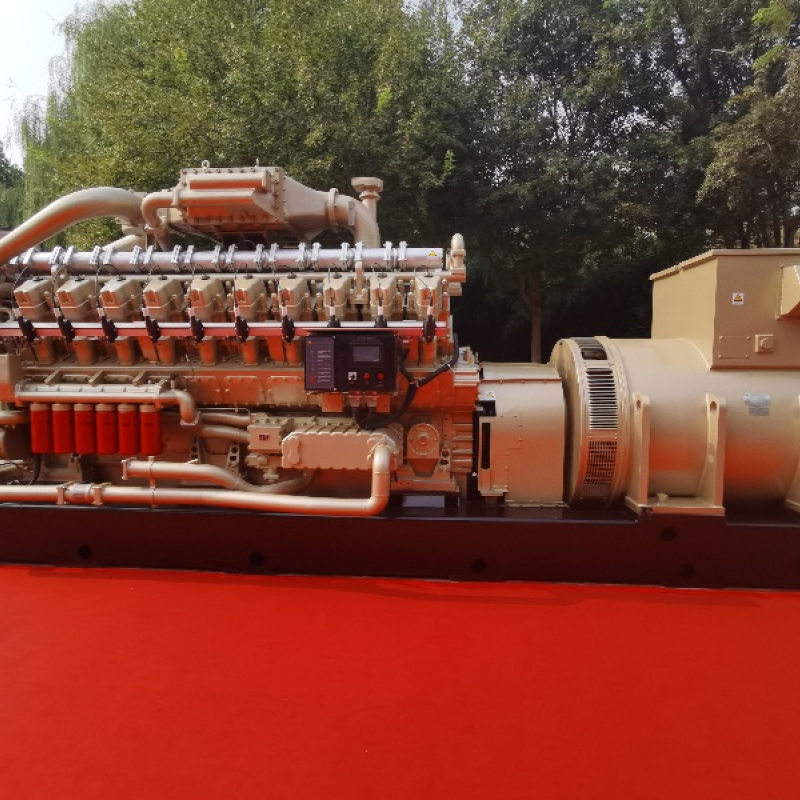

The engine has the characteristics of high power density, high efficiency, light weight, compact structure, long overhaul cycle and humanized maintenance design.The product is suitable for natural gas website, pressure pumping station, underground gas storage compression station and other projects, which can meet the needs of national energy conservation and emission reduction projects such as large gas power stations and distributed energy systems.The thermal efficiency of the engine is greater than 44%, and the power, economy and reliability have reached the international advanced level.Prod

Contact Now

Advanced genst management module (IG-NT automatic synchronization and automatic load distribution)Online maintenance technology (continuous trouble-free operation time more than 2500 hours)Digital monitoring technology (full monitoring of engine thermal parameters and unit electrical parameters)Distributed energy system (electric-thermal system, electric-hot-cold system)International mainstream control technology (EGS Engine Intelligent Management System)International advanced air-fuel ratio control technology (TECJET air-fuel ratio automatic regulation)Large flow and high pressure intake syst

Contact Now

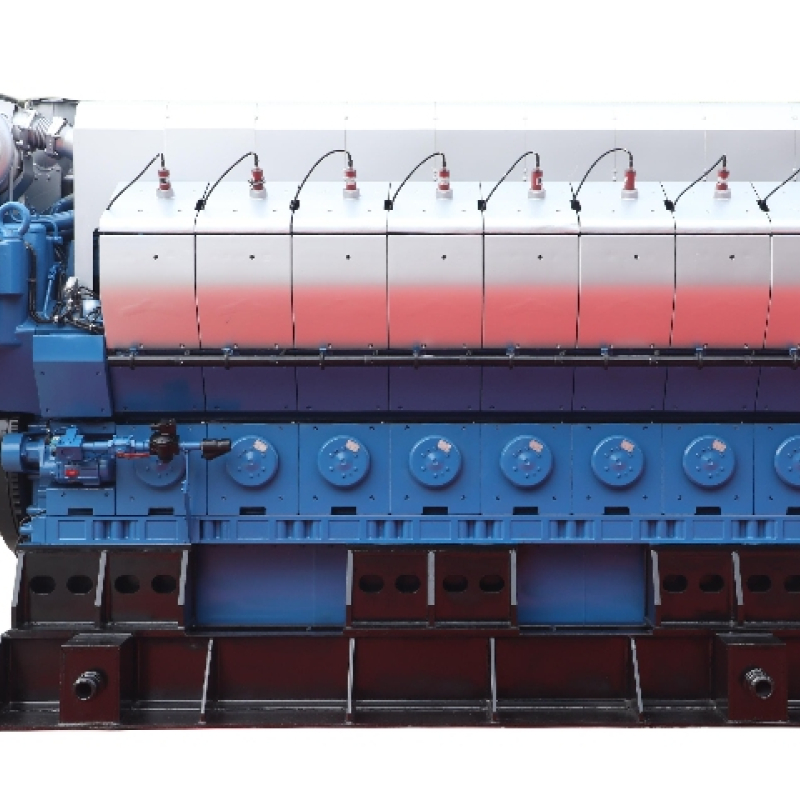

The product design is based on a 12V26/32 diesel engine, whose fuel involves diesel, heavy oil and natural gas. It is a high pressure engine with full intellectual property rights jointly developed by Geichai and AVL of Austria. It is a series of engines with 100% intellectual property rights, medium speed supercharged, great success, low fuel consumption, high reliability and long life, jointly developed by Geichai and AVL of Austria.

Contact Now

Product descriptionBiogas technology is a new energy comprehensive utilization technology integrating environmental safety and electricity saving. It uses a large amount of natural waste from industry, agriculture or urban life (such as distiller's grains, cow dung, municipal waste and sewage) to produce biogas through anaerobic fermentation.

Contact Now

Product descriptionThe natural gas generator -L20V190ZLT-1 engine, the engine is a 16V gas engine prototype design and manufacture of a high-intelligence, low heat consumption, high reliability, low emissions, long life of the 20V gas engine. L20V190ZLT-1 electronically controlled mixing engine speed of 1000r/min, stand-alone power of 2000kW. Instantaneous power up to 2200kW. The instantaneous power can be up to 2200kW.The gas engine generator system consists of natural gas engine, generator, general chassis, high elasticity coupling, control cabinet and so on.

Contact Now

Technical advantage1、Internal mixing gas injection and loop scavenging can effectively cool and clean cylinders,thereby ensuring that fuel can be controlledand saved;2、Isolated room of compressed air between compressor frame and engine piston can effectively prevent combustion exhaust fromreleasing to oil sump,prevent pollutions by lubricating oil and extend the service life;3、Power cylinder has a simple structure,without such wearing parts as rocker arm,tappet rod,cam,timing mechanism etc.,and with lessquick-wear parts and maintenance works;4、The special sulfur resistant design and manufactur

Contact Now

CNPC Chai Gas (coal mattress methane) electricity technology merchandise had beenfirst used in Jincheng region in 2003.

Contact Now

CNPC Chai Gas (coal bed methane) power generation products were first used in Jincheng area in 2003. Since 2005, the company has increased r&d investment in coal mine gas power generation products, paid attention to communication and cooperation with relevant research institutes of coal mines, and established close ties with China Coal Bed Methane Society, Henan University of Science and Technology, Fushun Coal Branch General Institute and other coal design institutes.

Contact Now

This series of units adopts the international advanced computer control technology, and the thin combustion technology is applied, aiming at the characteristics of coal mine gas concentration fluctuation, through the reasonable matching of the intake system, making this kind of products in the adaptability is particularly high, can adapt to all kinds of coal mine gas; Methane concentration can cover 8%-60%, pressure range 3-15kPa can be applied, its comprehensive performance, lubricating oil consumption, safety and reliability have reached the international leading level.

Contact Now