Accessories Policy:Quality and customer first, excellent service and quality based on the guarantee of parts life.Warranty: The warranty period of the compressor unit is 8,000 hours from the date of first operation after the completion of the installation acceptance test; Or within 1 year from the date of delivery (whichever comes first).

Contact Now

We have the most complete parts production and manufacturing system, storage system and transportation system to ensure that parts arrive in a fast way;We are one of the leading professional spare parts manufacturers and suppliers in China.

Contact Now

We are one of the most advanced professional spare parts suppliers in China.To provide you with qualified, high-quality and inexpensive accessories is our goal, equipment safe and efficient operation is the purpose; Accessories supply is the basis; The safe and efficient operation of the equipment is our common pursuit.

Contact Now

We have the most professional internal combustion engine parts production, quality inspection, supply, storage system, has the most complete parts sorting and packaging management chain, has a wealth of global parts delivery and supply experience; We have the technical consulting and diagnostic engineers who will reply to you immediately, and solve the problems in the operation of the equipment for you online; Provide equipment operation management consulting and suggestions; Video can help customers solve problems in operation.601.03.30BRocker arm cross bridge parts601.03.40Rotating mechanism

Contact Now

1, we have the most complete parts production and manufacturing system, storage system and transportation system, to ensure that parts arrive in a fast way;2, we have the most professional service and the best quality inspection system, to ensure that the accessories you receive are qualified, the best quality, the longest life.3, accessories are packed in cartons or wooden cases, fumigation-free, waterproof and moisture-proof, the safest protection.

Contact Now

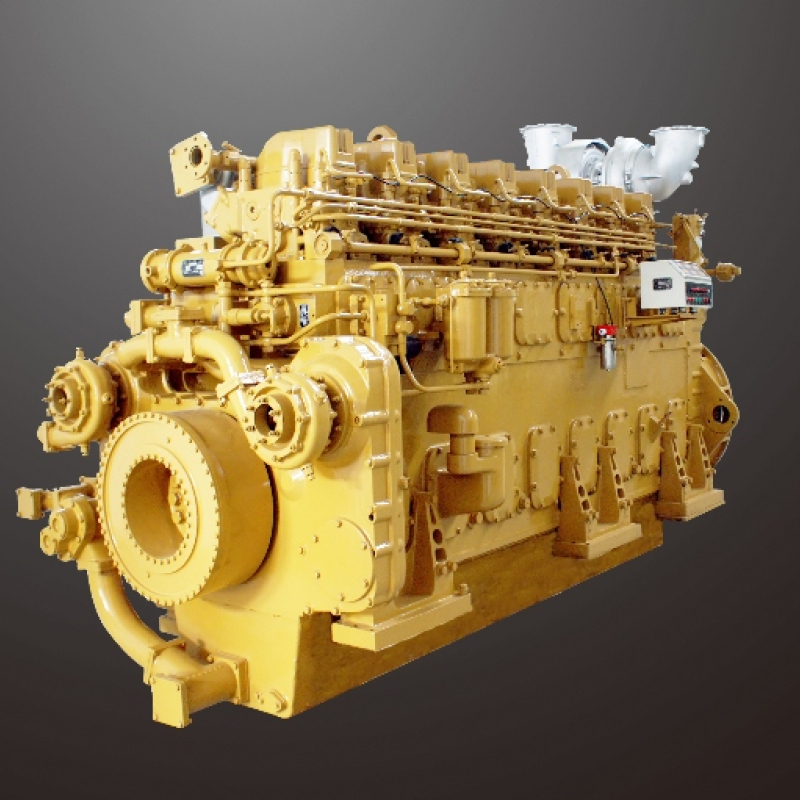

This model adopts the advanced technology of the current international high-power internal combustion engine industry, and configs the parts with mature technology to achieve a higher technical level in improving the average effective pressure in the internal combustion engine cylinder. At the same time, it reduces fuel consumption, improves reliability and safety, and expands the lateral vitality of the original 190 series diesel engine.

Contact Now

This type of product uses the international high-power internal combustion engine mature parts, while expanding the original 190 cylinder diameter series diesel engine power, reduce fuel consumption and emissions, improve the average effective pressure, improve the overall reliability and safety of the product. The series products are widely used in oil drilling business, Marine power, offshore drilling platform and other fields.

Contact Now

Characteristic(1) The large zero moment coefficient and high transmission efficiency can improve the working efficiency of the drilling machine.(2) To reduce or even eliminate the impact on the diesel engine and rig transmission parts, improve the service life.(3) When the rig is stuck or overloaded, the diesel engine will not shut off.(4) Even if the engine is running at full speed, the working mechanism of the rig (rotary table and drilling pump) can be operated for a long time at low speed by changing the amount of oil filled by the torque converter.(5) With the change of external load, the

Contact Now

Working mediumNatural gas, coal bed gas, shale gas, oil field associated gas, flash vapor, air, nitrogen, carbon dioxide, hydrogen, nitrogen hydrogen and so on.Spare parts supplyAccording to the loss of supporting parts, such as connecting rod, cross head, compression cylinder, distance plate, power piston, piston rod, power cylinder head, compression piston, compression piston rod, bearing bush, connecting rod bearing bush, copper bearing bush, cross head pin, air valve assembly, etc., the company has established a compressor spare parts library, which covers all kinds of parts and has suffic

Contact Now

Technical advantage1、Internal mixing gas injection and loop scavenging can effectively cool and clean cylinders,thereby ensuring that fuel can be controlledand saved;2、Isolated room of compressed air between compressor frame and engine piston can effectively prevent combustion exhaust fromreleasing to oil sump,prevent pollutions by lubricating oil and extend the service life;3、Power cylinder has a simple structure,without such wearing parts as rocker arm,tappet rod,cam,timing mechanism etc.,and with lessquick-wear parts and maintenance works;4、The special sulfur resistant design and manufactur

Contact Now

Technical Characteristics

1,Designed and manufactured as per API613 and ISO13631.;

2,Horizontally and symmetrically balanced sructure,with an accurate weight diference in reciprocating parts in each row,can effectively balance the inertia force and inetia moment,so that the compressor unit can operate with a small vibration and a low noise;

3.Highly stiff bare compressor mectanism optimized via mechanical treatment can eliminate wall surface vertical to force drection,so that the bearing capacity can be increased;

4.Bearing surtace of transmlsslon part is suoject to a low tpecific pressure val

Contact Now

The 6000 series diesel engine is carried out in cooperation with well-known scientific research institutions in China. Through cooperation with AVL of Austria, the engine combustion process is comprehensively optimized by using computer-aided software and the application of the latest development technology of internal combustion engine, and research tools such as simulation and finite element analysis.

Contact Now

The efficiency of its air exchange is higher than that of the natural intake of the general engine. When the air enters the turbocharger, its temperature will rise significantly, and the density will become smaller accordingly. The intercooler plays the role of cooling the air, and the high-temperature air is cooled by the intercooler and then enters the engine. If the lack of an intercooler and let the pressurized high temperature air directly into the engine, it will cause the engine to knock or even damage the flame.

Contact Now

The T engine in the series can also be regarded as an improved model on the basis of the 6000 series diesel engine in the application field, and its power performance and economic indicators have been greatly improved. The design structure of two end output crankshaft is adopted, and the connection mode of output end is designed according to SAE standard. It can be matched with gearbox and pump groups and is widely used in transport and construction ships.

Contact Now

This type of product adopts the medium speed supercharging technology route, is a high-power, low fuel consumption, high reliability, long life engine series.

Contact Now

The engine adopts the modular design concept, adopts the "high pressure common rail", "high pressure closed respiratory system" and other international advanced internal combustion engine technology, the product meets the low emission standards, and is widely used in Marine engineering.Engine Series140 marine engine(300-457KW)Engine ModelJC15C-3 marine engineTypeFour stroke, supercharged intercooling, water cooling, high pressure common rail ECU electronic control jetCylinders & Arrangement6 cylinders, in-lineCylinder bore,mm140Piston Bore,mm165Rated Power,kW/hp300/408R

Contact Now

The engine adopts modular design, high pressure common rail, high pressure, closed breathing system and other advanced international internal combustion engine technology, meet the low emission standards, widely used in ship projects. Engine Series140 marine engine(300-457KW)Engine ModelJC15C-3 marine engineTypeFour stroke, supercharged intercooling, water cooling, high pressure common rail ECU electronic control jetCylinders & Arrangement6 cylinders, in-lineCylinder bore,mm140Piston Bore,mm165Rated Power,kW/hp450/612RPM,r/min1800Total Piston Displacement ,L15.2Fuel oil consumption ra

Contact Now

MAN is the world's leading designer and manufacturer of medium and low-speed diesel engines, which account for nearly 50% of the world's tradable powerIts products use a unique large engine technology.Optimize power and fuel consumption rates while reducing emissions.The product has strong dynamic performance and good economy.High reliability, high safety, good environmental protection quality.Product Series320 Marine EngineModel8L3240TypeFour stroke, supercharged intercooling, water cooling, high pressure common rail ECU electronic control jetCylinders & Arrangement8 cylinders, in

Contact Now

The redesign of the gearbox can be applied to reduce the impact of speed and load on transport and construction vessels. At the same time, it can also meet the requirements of dual starting (gas starting and electric starting), remote automatic operation, and parallel engine operation. The product has a wide range of power coverage, which can meet the needs of customers in different power sizes, adapt to different ship types and other market segments.

Contact Now

The product design is based on a 12V26/32 diesel engine, whose fuel involves diesel, heavy oil and natural gas. It is a high pressure engine with full intellectual property rights jointly developed by Geichai and AVL of Austria. It is a series of engines with 100% intellectual property rights, medium speed supercharged, great success, low fuel consumption, high reliability and long life, jointly developed by Geichai and AVL of Austria.

Contact Now

12V175 diesel engine has the characteristics of high pressure, low energy consumption, high reliability and long life. By using new technologies such as electronic control, high pressure common rail, Miller cycle, tail gas after-treatment and high efficiency supercharger, the engine power, economy, reliability and emission index have reached the international advanced level.

Contact Now

It can meet the requirements of gas and electricity double starting, remote operation, engine parallel and so on.The products cover a wide range of power, can meet the needs of customers in different power segments, products have passed the CCS certification.Engine Series2000 series(330-1320KW)Engine Model6190ZLC-3 marine engineTypeFour stroke, pressurized intercooled, water-cooled, direct-injection combustorCylinders & Arrangement6 cylinders, in-lineCylinder bore,mm190Piston Bore,mm210Rated Power,kW/hp400/540RPM,r/min1200Total Piston Displacement ,L35.73Fuel oil consumption rate,g/kW.h≤20

Contact Now

The gearbox can be used to reduce the speed and load of transport ships and engineering ships. It can meet the requirements of gas and electricity double starting, remote operation, engine parallel and so on.The products cover a wide range of power, can meet the needs of customers in different power segments, products have passed the CCS certification.

Contact Now

Product feature:100% intellectual property of companyInternational Control Technology (EGS Engine Management System))International mainstream air-fuel ratio control technology (TECJET air-fuel ratio automatic regulation management system)Large flow and high pressure intake automatic management system of adapting to a wide range of concentration changesLow pressure intake and rarefied gas combustion control technology (suitable for low pressure gas, lower emission)Engine seriesEngine modelEngine modelH16V190ZLT-1 gas engineCylinders & Arrangement16 cylinders V typeCylin

Contact Now