One of the direct consequences of the blockage of the supercharger channel is to increase the resistance of the airflow in the system. When the engine is running, the gas flow route of the pressurization system is: compressor inlet filter and muffler → compressor impeller → compressor diffuser → air cooler → scavenging box → diesel engine intake port (valve) → exhaust port (valve) → exhaust pipe → exhaust turbine nozzle ring → exhaust turbine impeller → chimney. The circulation area of each component is fixed.

Contact Now

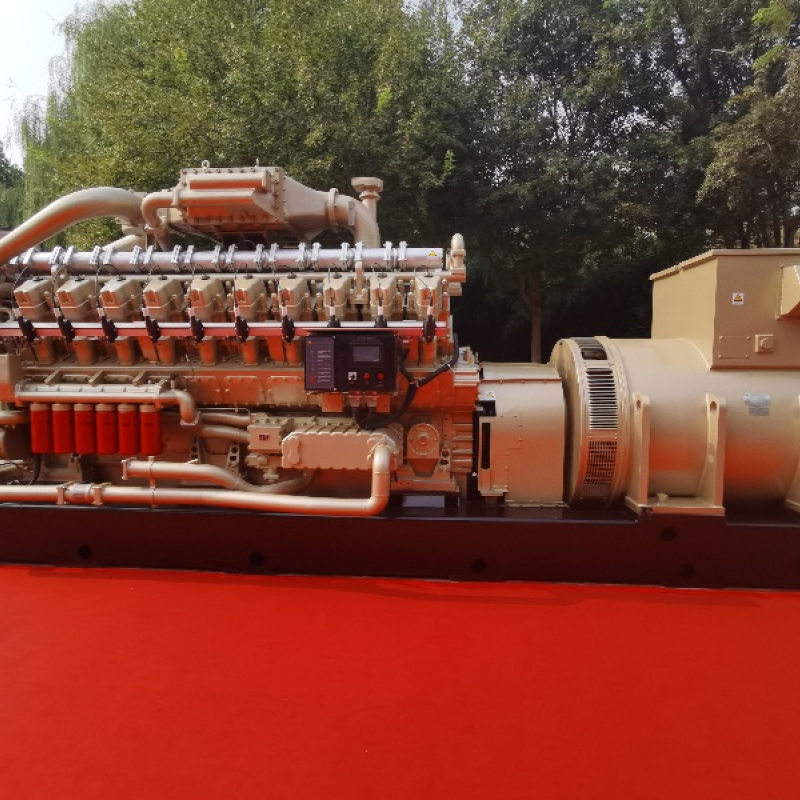

12V175 diesel engine has the characteristics of high pressure, low energy consumption, high reliability and long life. By using new technologies such as electronic control, high pressure common rail, Miller cycle, tail gas after-treatment and high efficiency supercharger, the engine power, economy, reliability and emission index have reached the international advanced level.

Contact Now

Fast response service, complete quality system, huge storage system, fast logistics system; These are our professional embodiment, do accessories we are professional.

Contact Now

According to the characteristics of oilfield working conditions, the genset has been designed in terms of starting performance, sudden reduction capacity and continuous working capacity.

Contact Now

The efficiency of its air exchange is higher than that of the natural intake of the general engine. When the air enters the turbocharger, its temperature will rise significantly, and the density will become smaller accordingly. The intercooler plays the role of cooling the air, and the high-temperature air is cooled by the intercooler and then enters the engine. If the lack of an intercooler and let the pressurized high temperature air directly into the engine, it will cause the engine to knock or even damage the flame.

Contact Now

Characteristic(1) The large zero moment coefficient and high transmission efficiency can improve the working efficiency of the drilling machine.(2) To reduce or even eliminate the impact on the diesel engine and rig transmission parts, improve the service life.(3) When the rig is stuck or overloaded, the diesel engine will not shut off.(4) Even if the engine is running at full speed, the working mechanism of the rig (rotary table and drilling pump) can be operated for a long time at low speed by changing the amount of oil filled by the torque converter.(5) With the change of external load, the

Contact Now

2000 series diesel engine has high market volume, high maturity, a long history, with compact structure, long overhaul cycle, humanized maintenance design and other characteristics.Product series2000 (500-800kw)Genset model500GF17-2 diesel genset700GF1-3 diesel genset800GF4-7 diesel genset800GFZ-1 diesel gensetEngine modelG12V190ZLD1-2G12V190ZLD1G12V190ZLD2G12V190ZLD3Power kW500700800800RPM,r/min1000150015001500Voltage V400/6300/10500Frequency Hz50Power factor

Contact Now

Jichai 140 series diesel engine is a high performance and high speed diesel engine with all intellectual property rights developed by Jichai and AVL.The products are mainly used in light oil rigs, petroleum machinery, and mobile power stations, construction machinery, heavy trucks and other fields.Can meet all kinds of power generation needs.It has the characteristics of compact shape, simple operation and maintenance, and high power index.

Contact Now

Jichai 140 series diesel engine is a high-performance high-speed diesel engine with all intellectual property rights developed by Jichai and AVL. The products are mainly used in light oil drilling rigs, petroleum machinery, and mobile power stations, construction machinery, heavy trucks, and other fields. Can meet all kinds of power generation needs.

Contact Now

Series 6000 land-used diesel engine is developed by using Jichai with Austria AVL enterprise and home generic faculties and universities, lookup institutes, and by usingcapacity of the modern day improvement of inner combustion engine, thru the computer-aided design, simulation, finite aspect evaluation and lookup on the combustion process, the crankshaft torsional vibration of engine and turbocharger matching, into the exhaust machine on the groundwork of

Contact Now

Main technical characteristics: ◆advanced performance indicators: modular pieces oil high-pressure common rail fuel injection system ◆High reliability: the main important pieces of 3 d modeling optimization design of high strength ◆High strength, high stiffness, low noise: frame type main bearing structure, integral main bearing base, through type main bearing bolts ◆Low fuel consumption, low emissions: single cylinder head, 4 valves intake and exhaust structure, optimize the intake and exhaust duct and combustion, cooling system reasonable match.G

Contact Now

This series of diesel engine is based on the Z12V190B diesel engine, the reliability, economy and power of the diesel engine has been comprehensively improved and upgraded, to solve the problem of three leaks, while the appearance quality and maintenance have been greatly improved, so as to better meet the power requirements of various oil RIGS, generator sets and construction machinery.DescriptionGenset modelRated power kwRatation speed r/minEngine modelHydraulic transmission couplerHeight of centerHydraulic transmission coupling setG12V190PZL-1/O engine with hydraulic coupling7401

Contact Now

Series 26/32 heavy oil machine is a new product developed by Jichai to meet the needs of China's economic and environmental development and Jichai owns all independent intellectual property rights. The key technical indexes of series 26/32 heavy oil engines, such as average pressure, fuel consumption rate, single cylinder power and emission, have all reached or exceeded the international advanced level.Because it burns heavy oil, it greatly reduces the running cost of the engine, and has high reliability, low emission and high intelligence and other characteristics.

Contact Now

Series 32/40 heavy oil computing device is a new product developed by using Jichai to meet the wants of China's financial and environmental improvement and Jichai owns all unbiased mental property rights.

Contact Now

We are one of the professional component suppliers and manufacturers in China;Our products are available globally; We have meticulous and professional services; We have a complete warehousing and transportation system.

Contact Now

MAN is the world's leading designer and manufacturer of medium and low-speed diesel engines, which account for nearly 50% of the world's tradable powerIts products use a unique large engine technology.Optimize power and fuel consumption rates while reducing emissions.The product has strong dynamic performance and good economy.High reliability, high safety, good environmental protection quality.Product Series320 Marine EngineModel8L3240TypeFour stroke, supercharged intercooling, water cooling, high pressure common rail ECU electronic control jetCylinders & Arrangement8 cylinders, in

Contact Now

The gearboxes are used for deceleration and load shedding in transport and construction vessels. The products cover a wide power range to meet the needs of customers in different power segments, and the products have passed CCS certification.ModelCylinders & ArrangementCylinders bore,mmPiston stroke,mmRated power,kw/hpRPM,r/minTotal piston displacement,LFuel oil consumption rate,g/kW.hLub.

Contact Now

High pressure steel wire braided hose operating temperature: oil -40℃ ~ 100℃, air -30℃ ~ 50℃, water emulsion +80℃ below.High pressure steel wire braided hose specification range: DN5mm ~ DN102mm.

Contact Now

CNPC Ji Chai Gas (coal bed methane) power generation products were first used in Jincheng area in 2003. Since 2005, the company has increased r&d investment in coal mine gas power generation products, paid attention to communication and cooperation with relevant research institutes of coal mines, and established close ties with China Coal Bed Methane Society, Henan University of Science and Technology, Fushun Coal Branch General Institute and other coal design institutes.

Contact Now

Product descriptionLandfill gas engine generators are well-established products in our product line. After years of painstaking research, the product incorporates the rich profit-making experience of the 12V190 gas engine, and the automation function of the unit is significantly enhanced. Reliable air-fuel ratio automatic control technology enables the unit to have higher gas applicability, stronger comprehensive performance and economy, and successfully reduces the emission index to the minimum.

Contact Now

The 140 series engine is another small-bore unit jointly developed by Jichai and AVL, which is a high-performance high-speed engine with full intellectual property rights of the company.

Contact Now

Precision engine management system;Fine control of main combustion chamber and pre-combustion chamber;Load balancing controlLeading thermal efficiency (international :42-45%; Current test thermal efficiency :44%);System safety (installation of explosion-proof device, double-wall gas pipe and oil mist detector);Thin combustion in the cylinder;Ultra-low emission;Self-cleaning filtration technologyThe oil filter can be automatically cleaned without replacing the filter.

Contact Now

Jichai began developing high-power turbocharged natural gas engines in 1982. From 1984 to 1988, three prototype tests were carried out in the laboratory, 10,000 hours of industrial tests were carried out in Shengli Oilfield, and on October 12, 1988, it was recognized by the state as a 600kW/1000r/min external hybrid supercharged high-power gas engine.

Contact Now

CNPC Chai Gas (coal mattress methane) electricity technology merchandise had beenfirst used in Jincheng region in 2003.

Contact Now