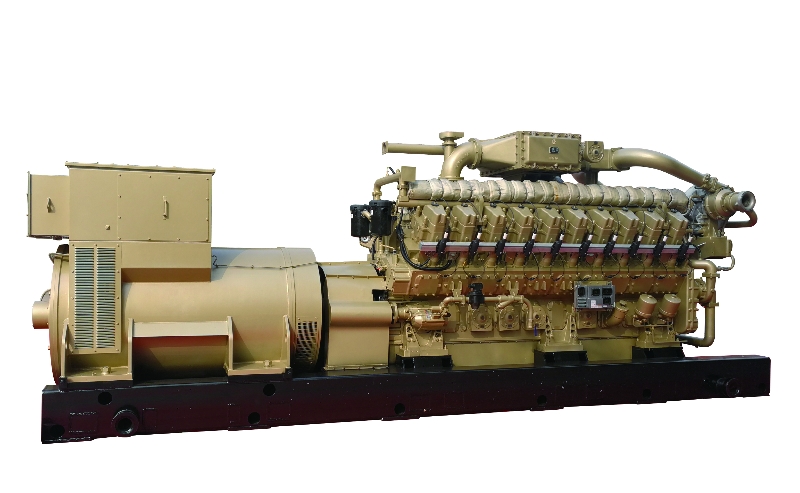

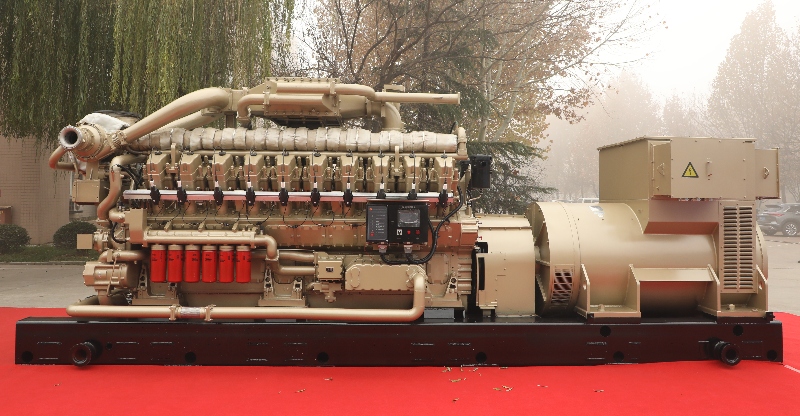

2000kW Gas Generator Set

It is necessary to develop 190 series gas generator sets covering the power segment of 1000kW~2000kW, so as to maintain the cost advantage over foreign gensets, expand the power coverage, continue to improve the competitiveness of 190 series gas generator sets, and maintain the competitive advantage of providing firewood.

The single power of the long-stroke 20V190 gas engine covers the power segment of 1000kW~2000kW, and the gas type can take into account natural gas, gas and biogas, which has a broad market demand prospect.

L20V1902LT-2type closed-loop electrically controlled external mixing natural gas machine features:

1、Turbocharger pre-mixing technology, where gas and air are sucked in at the same time in the compressor, to be suitable for low pressure gas,

2,The rarefied combustion technology uses WOODWARD's E6 control system to accurately control the air-fuel ratio.Reach the high - altitude combustion ratio, achieve rarefied combustion

3,The single point injection and air - fuel ratio closed - loop control technology can realize the closed - loop control of air - fuel ratio (in).The engine can adjust the amount of air and natural gas according to the requirements of different working conditions and different speeds, so that the engine can run in the best state.

4,Efficient and reliable design of the intake and exhaust system, the use of advanced high pressure ratio, large flow supercharger, increase the flow area of the intake pipeline, improve the intake efficiency

5,High efficiency, low resistance and plate type oil cooler to improve cooling efficiency, increase the cooling area of air and lubricating oil.

6、The ignition system with high energy and high reliability is selected to make the combustion of each cylinder of the engine more stable and even.

Engine Technical parameters | |

Model | L20V190ZLT-2 |

Type | Four stroke, turbocharging, air intercooling, water cooling, electronic control, air-fuel ratio control, compressor pre mixing, spark plug ignition |

Cylinderarrangement | 20 cylinder V type, 60° intersection angle |

Cylinder * stoke | 190×255mm |

Total displacement | 144.6L |

Compression ratio | 10:01 |

Piston average speed | 8.5m/s |

Rated speed | 1000r/min |

Idle speed | 700r/min |

Rated power | 2000kW |

Heat consumption rate | ≤9000kJ/kW·h |

Heat efficiency | 40% |

Gas inlet pressure | 7-9 KPa |

Gas filter | can change filter element without stopping the machine |

Lubrication consumption | ≤1.0g/kW.h |

Lubrication model | 15W-40 |

Lubricating method | Pressure and splash lubricating |

Lubrication filter | centrifugal filter+paper refined dual filter system,can change filter element without stopping the machine |

Exhaust temperature | ≤680℃(涡轮前)( before turbo) |

Speed regulating | electronically speed regulation |

Stably speed regulation rate | 0-5%regulated |

A/F ratio control method | E6 electronic controller |

Ignition control system | Mic4 ignition system |

Cooling method | Water forced cooling |

Freeze protection | Change anti-freezing liquid as per requirement in winter |

Noise | <110dB |

Silencer type | Fire extinguishing type air exhaust silencer |

Explosion protection | inlet pipe, crankshaft box |

Cooling water temperature high protection | Alarm in 95℃ |

Lubricating oil temperature high protection | Alarm in 100℃ |

Lubricating oil pressure low protection | ≤0.25MPaAlarm and stop |

High speed protection | ≥112% Alarm and stop |

Engine data collection | Use communication port RS485 |

Rotation direction of crankshaft | Anti-clockwise |

After-sales service

1. The professional engineers will answer your questions during pre-sales consultation.

2. There are engineers in the sale for you to debug and train the generator set.

3. The telephone engineers can provide technical support 24 hours a day worldwide.

Packaging and delivery

Products are packaged in bulk, container, standard export packaging or custom packaging. Then select the appropriate means of transport according to the number of boxes. The goods are inspected many times before shipment to ensure that the products are in good condition and that every delivery we make is to the satisfaction of our customers.